Ship ManagementOur History

History of our offshore vessel services for the past four decades and recent examples of ship management

Timeline of Kyoei Marine offshore vessel management for over 40 years

1980

Establishment of the company.

1981

Started managing ocean tugboats for towing and salvage.

1981

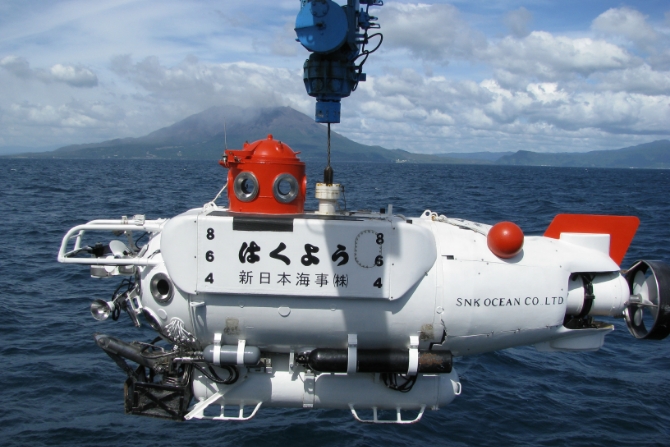

Started managing vessels loaded with manned submersibles.

1992

Started managing vessels loaded with remotely operated vehicles (ROV).

2000

Started managing vessels equipped with dynamic positioning systems (DPS).

2004

Started managing vessels loaded with streamer cable for bathymetric surveys.

2015

Started managing vessels with moon pools for deploying drills and other equipment to the seafloor.

2023

Started managing one of the world’s foremost self-propelled SEP vessel.

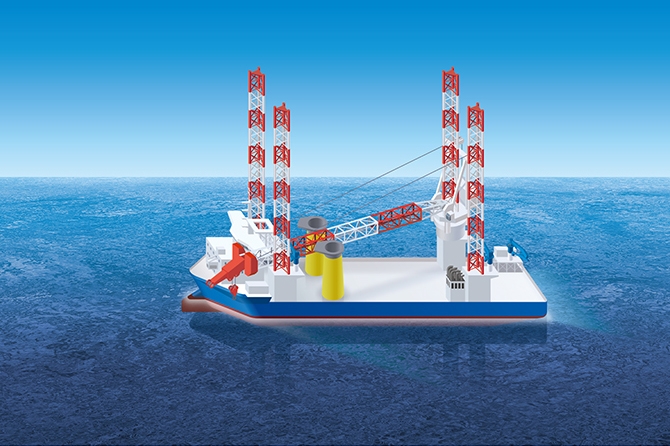

Management of one of the world’s biggest jack-up vessels (SEP ship) for offshore wind farm construction.

We have been entrusted with the management of one of the world’s biggest jack-up vessels (SEP: Self-Elevating Platform) for offshore wind farm construction based on our excellent track record in offshore vessel management.

In addition to proven technologies such as the Dynamic Positioning System and azimuth thruster (360-degree propeller), we support emerging technologies like jacking systems and super-large cranes for the management of every type of offshore vessel.

Offshore Wind Turbine Installation Process

Loading offshore wind turbines on a SEP ship

After entering the port, offshore wind turbines are loaded onto the SEP.

The typical length of an 8MW offshore wind turbine is approx. 80m for blades and 105m for a tower.

Jack-up and setting

The SEP moves to an installation point where it is elevated with four feet while being positioned by the DPS before commencing turbine set-up work.

Jack-down

After the installation of the turbine, the SEP is jacked down and moves to the next installation point.

Installing the other turbines

The above steps are repeated to install the other turbines at their respective installation points.